The spread of the hearth up the skin wall, if any, was then monitored. The Independent Expert Advisory Panel additionally suggested the division to establish a research venture to check and improve the evidence obtainable on the behaviour of a spread of non-ACM supplies used in cladding systems when subjected to fireside.

With the event of an equilibrium pore and crack construction within the oxide layer, the oxidation fee effectively turns into linear, a attribute characteristic of the submit-transition oxidation habits. Alloying components, particularly tin, niobium, and iron, current in the α-solid resolution strongly affect each the kinetics and the mechanism of oxide development in zirconium alloys. The thickness of the cladding is a design parameter dictated by conflicting performance requirements.

In response to this unforeseen consequence, several fixes were introduced. In one, a second internal-surface liner of ordinary Zry is extruded on the sponge zirconium liner in order to restore corrosion resistance.

Metal is probably the most power-efficient and sustainable constructing supplies obtainable. Next to this it is nearly utterly recyclable and current metallic coils contain a high recycling content as much as 95%. The engineering of our materials additionally makes our cladding a strong resilient type of exterior covering . The bonding agent reinforces the picket parts, and our additives enhance the cladding’s climate resistance.

tube. Energy, from fission, is generated roughly uniformly all through the gas pellets. Heat is extracted on the rod floor by the coolant move. The temperature at the hottest level, on the pellet centerline, is often in the vary 800–1000 °C, relying on the power level. The metallic cladding is a good conductor, so the temperature rise across the wall is just a few tens of levels.

During mechanical decladding, the gas assemblies are chopped and the gas core is leached with nitric acid, leaving behind the undissolved cladding materials for disposal as a stable waste. This method is adopted for zircaloy-clad fuels from power reactors and stainless-steel-clad quick reactor fuels. Cladding gear is usually designed to suit a specific product or a bunch of merchandise; this notably applies to the items required for uncoiling of the strip and the feeding device. The material and floor of the rolls as well as their geometrical form (cylindrical or topped) are crucial. Depending on the materials to be bonded, cleaning and roughening are finest carried out by brushing, grinding, or scraping utilizing a specifically designed cutter with needles.

The buildup of those may be suppressed by including hydrogen within the coolant water. Dissolved hydrogen concentration in PWR coolant is maintained at a degree of two.2–four.5 ppm with a view to enhancing recombination with oxygen radicals formed by radiolysis. The PHWR coolant does not include boric acid and deuterium is added instead of hydrogen. Dissolved oxygen in PHWR coolant is managed between 10–50 ppb and it has been noticed that corrosion in both zircaloy-2 and Zr-2.5 Nb strain tubes rises to an exceptionally high worth at high oxygen concentrations.

.gbip::beforecontent:url(https://ssl.gstatic.com/gb/images/silhouette_96.png)@media (min-resolution:1.25dppx),(-o-min-device-pixel-ratio:5/4),(-webkit-min-device-pixel-ratio:1.25),(min-device-pixel-ratio:1.25){.gbii::beforecontent:url(https://ssl.gstatic.com/gb/images/silhouette_27.png).gbip::before

.gbip::beforecontent:url(https://ssl.gstatic.com/gb/images/silhouette_96.png)@media (min-resolution:1.25dppx),(-o-min-device-pixel-ratio:5/4),(-webkit-min-device-pixel-ratio:1.25),(min-device-pixel-ratio:1.25){.gbii::beforecontent:url(https://ssl.gstatic.com/gb/images/silhouette_27.png).gbip::before

Grenfell Tower: second phase of inquiry ‘could be delayed until 2020’

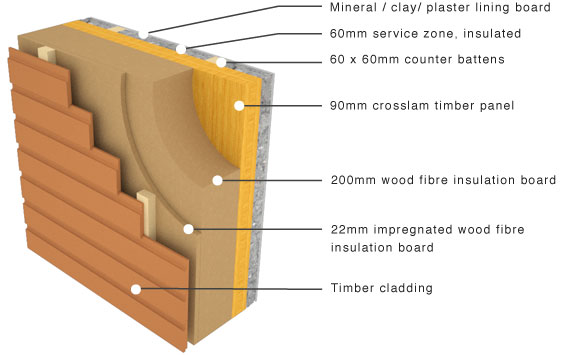

A suction removing unit is used to evacuate rigorously any materials waste so as to avoid bonding flaws because of poor adhesion. Hanover House, a residential tower block in Sheffield, with its cladding partially eliminated after failing hearth safety exams following the Grenfell Tower hearth. Cladding in development is materials applied over one other to provide a skin or layer and used to offer a degree of thermal insulation and weather resistance, and to enhance the appearance of buildings. Between the cladding and the wall there is a cavity where rain can run down. an industrial primer of wood for facade cladding and prefabricated elements for picket homes.

Most of the metal cladding for the building business is pre-painted in coil prior to the production of the cladding panels. Metal cladding is used for both protection from environmental components and aesthetics of the building. The paint applied by coil coating provides the metal more durability, corrosion resistance and ultimate look. Arconic argued that the tragedy at Grenfell was not the results of its panels, however the mixture of materials used within the 2016 £10m refurbishment, singling out the plastic window frames through which the hearth was believed to have first unfold from flat 16 into the cladding system.

In different modifications, the sponge zirconium is alloyed with iron or tin to improve oxidation resistance with out affecting the softness that provides immunity from PCI. scale that grows around them throughout in-reactor operation. This loss of the insulating properties of the oxide is believed to speed up the corrosion price.

In addition to metallurgical components, water chemistry has a robust influence on the corrosion process in zirconium alloys. The control of water chemistry as required in several reactor techniques embrace suitable additions of lithium hydroxide, boric acid, hydrogen/deuterium, oxygen, iron, and zinc. In PWRs, boric acid is added to the coolant water for reactivity control. The pH of the coolant is adjusted by addition of lithium hydroxide which renders the coolant barely alkaline, in order to reduce the corrosion charges of structural materials (stainless steels and Inconels) in the primary warmth transport circuit and thereby inhibit deposition of corrosion merchandise on the gas cladding. Radiolysis of water produces oxidizing species which reinforces oxidation fee of zirconium alloys within the radiation surroundings .

Moore-Bick has confronted widespread calls to conclude in his interim report – expected subsequent spring – that the £10m refurbishment, utilizing extremely flamable cladding panels, was in breach of constructing regulations. But he has also heard conflicting evidence about whether the fire brigade ought to have tried to order a full evacuation earlier than the constructing was engulfed in flames trapping and killing families and friends who huddled together in flats. Earlier in Wednesday’s hearing firefighters blamed the Royal Borough of Kensington and Chelsea for failing to make an evacuation plan for Grenfell Tower, regardless of expert recommendation taken before the catastrophe and legal obligations making clear it was needed. The efficiency of the uPVC home windows within the fourth flooring flat the place the fireplace began, the synthetic insulation and other decorative cladding panels across the remainder of the constructing had been successfully responsible for spreading the fireplace, he mentioned.

Grenfell Tower: second phase of inquiry ‘could be delayed until 2020’

Modified low-tin alloys can be used both as an entire substitute for the Zry tube wall or as a skinny outer skin on normal Zry substrate tubing. 1.5% tin, and the balance being iron, nickel, and chromium. Its commercial title is Zircaloy, or Zry for brief.

In response to this unforeseen consequence, a number of fixes had been introduced. In one, a second internal-surface liner of ordinary Zry is extruded on the sponge zirconium liner to be able to restore corrosion resistance.

A suction removing unit is used to evacuate fastidiously any material waste so as to avoid bonding flaws because of poor adhesion. Hanover House, a residential tower block in Sheffield, with its cladding partially eliminated after failing hearth safety exams following the Grenfell Tower fireplace. Cladding in construction is material utilized over another to provide a skin or layer and used to supply a level of thermal insulation and weather resistance, and to enhance the appearance of buildings. Between the cladding and the wall there's a cavity the place rain can run down. an industrial primer of wood for facade cladding and prefabricated parts for wooden homes.

Zircaloys have anisotropic bodily, mechanical, and chemical properties. Within the oxide layer, the alloying parts affect the atomic transport such that the alloying concentration determines the corrosive behavior, with excessive alloying concentrations (above ∼zero.6%) providing safety in opposition to oxide progress. Today, Zircaloy-2 and Zircaloy-four are widely used.

The joint is then attributable to a deformation-induced melting bath. The melt layer is kind of skinny; for instance, when cladding an aluminum alloy it's about 0.5–fourμm (Kreye 1985, 1997 ). The dilution of the molten zones leads to airplane or corrugated interfaces.

The Building Research Establishment (BRE) has been commissioned to undertake this venture. This programme is on-going and checks are anticipated to conclude in the summertime.

These frameworks have been applied and peer reviewed throughout the scope of fireplace analysis studies on the hearth efficiency of aluminium composite panels and insulation materials at The University of Queensland and the University of Edinburgh. This massive scale take a look at, undertaken by the Fire Protection Association (FPA), tested a HPL panel system with stone wool insulation, in accordance with British Standard 8414. This check entails building a 9-metre excessive wall with an entire cladding system fixed to it - including panels and insulation. This was then subjected to a fireplace designed to copy the circumstances by which a severe fireplace breaks out of a window.

As a remedy, rapid cooling of the Zry ingot throughout fabrication (referred to as beta quenching) produces a a lot finer intermetallic precipitate population. This distribution of the transition metals maintains the power of the Zry however improves its corrosion resistance, possibly by brief-circuiting charge-transport paths between the scale floor and the metal–oxide interface. In order to eliminate waterside corrosion of cladding as a life-limiting process, modified Zircaloys have been developed. Under PWR water situations, decreasing the tin content of Zry to 1% and including a comparable focus of niobium produces an alloy with a corrosion fee several occasions lower than that of the usual Zry.

The oxidation process and the nature of the oxide layer on a zirconium alloy sample are schematically illustrated in Fig. 6 .

During mechanical decladding, the gasoline assemblies are chopped and the gasoline core is leached with nitric acid, leaving behind the undissolved cladding materials for disposal as a solid waste. This technique is adopted for zircaloy-clad fuels from energy reactors and chrome steel-clad quick reactor fuels. Cladding gear is usually designed to swimsuit a specific product or a gaggle of merchandise; this notably applies to the items required for uncoiling of the strip and the feeding tool. The material and floor of the rolls in addition to their geometrical form (cylindrical or topped) are crucial. Depending on the supplies to be bonded, cleansing and roughening are finest carried out by brushing, grinding, or scraping using a specially designed cutter with needles.

In addition to metallurgical elements, water chemistry has a robust influence on the corrosion process in zirconium alloys. The control of water chemistry as required in several reactor systems embody suitable additions of lithium hydroxide, boric acid, hydrogen/deuterium, oxygen, iron, and zinc. In PWRs, boric acid is added to the coolant water for reactivity management. The pH of the coolant is adjusted by addition of lithium hydroxide which renders the coolant slightly alkaline, to be able to cut back the corrosion rates of structural materials (stainless steels and Inconels) in the main heat transport circuit and thereby inhibit deposition of corrosion products on the fuel cladding. Radiolysis of water produces oxidizing species which reinforces oxidation rate of zirconium alloys within the radiation setting .

.gbip::beforecontent:url(https://ssl.gstatic.com/gb/images/silhouette_96.png)@media (min-resolution:1.25dppx),(-o-min-device-pixel-ratio:5/4),(-webkit-min-device-pixel-ratio:1.25),(min-device-pixel-ratio:1.25){.gbii::beforecontent:url(https://ssl.gstatic.com/gb/images/silhouette_27.png).gbip::before

.gbip::beforecontent:url(https://ssl.gstatic.com/gb/images/silhouette_96.png)@media (min-resolution:1.25dppx),(-o-min-device-pixel-ratio:5/4),(-webkit-min-device-pixel-ratio:1.25),(min-device-pixel-ratio:1.25){.gbii::beforecontent:url(https://ssl.gstatic.com/gb/images/silhouette_27.png).gbip::before

Dictionary Entries near more cladding

.gbip::beforecontent:url(https://ssl.gstatic.com/gb/images/silhouette_96.png)@media (min-resolution:1.25dppx),(-o-min-device-pixel-ratio:5/4),(-webkit-min-device-pixel-ratio:1.25),(min-device-pixel-ratio:1.25){.gbii::beforecontent:url(https://ssl.gstatic.com/gb/images/silhouette_27.png).gbip::before

.gbip::beforecontent:url(https://ssl.gstatic.com/gb/images/silhouette_96.png)@media (min-resolution:1.25dppx),(-o-min-device-pixel-ratio:5/4),(-webkit-min-device-pixel-ratio:1.25),(min-device-pixel-ratio:1.25){.gbii::beforecontent:url(https://ssl.gstatic.com/gb/images/silhouette_27.png).gbip::before

The interplay that gas cladding tubes expertise due to the fission merchandise on the internal surface is stress corrosion cracking (SCC). Iodine, caesium, and cadmium are a number of the fission products which contribute strongly to the SCC process.

The buildup of those may be suppressed by including hydrogen within the coolant water. Dissolved hydrogen concentration in PWR coolant is maintained at a level of 2.2–4.5 ppm with a view to enhancing recombination with oxygen radicals formed by radiolysis. The PHWR coolant does not include boric acid and deuterium is added in place of hydrogen. Dissolved oxygen in PHWR coolant is managed between 10–50 ppb and it has been noticed that corrosion in each zircaloy-2 and Zr-2.5 Nb pressure tubes rises to an exceptionally high value at high oxygen concentrations.

A suction removal unit is used to evacuate rigorously any materials waste so as to avoid bonding flaws as a result of poor adhesion. Hanover House, a residential tower block in Sheffield, with its cladding partially eliminated after failing fireplace safety checks following the Grenfell Tower fire. Cladding in construction is materials utilized over one other to supply a skin or layer and used to supply a degree of thermal insulation and climate resistance, and to improve the appearance of buildings. Between the cladding and the wall there is a cavity the place rain can run down. an industrial primer of wood for facade cladding and prefabricated parts for wooden homes.

Most of the metallic cladding for the constructing trade is pre-painted in coil previous to the manufacturing of the cladding panels. Metal cladding is used for both safety from environmental factors and aesthetics of the constructing. The paint applied by coil coating gives the metallic more sturdiness, corrosion resistance and ultimate look. Arconic argued that the tragedy at Grenfell was not the results of its panels, however the mixture of materials used within the 2016 £10m refurbishment, singling out the plastic window frames via which the hearth was believed to have first spread from flat 16 into the cladding system.

These frameworks have been applied and peer reviewed inside the scope of fire analysis studies on the fire efficiency of aluminium composite panels and insulation supplies at The University of Queensland and the University of Edinburgh. This massive scale test, undertaken by the Fire Protection Association (FPA), tested a HPL panel system with stone wool insulation, in accordance with British Standard 8414. This check includes building a 9-metre excessive wall with an entire cladding system fixed to it - together with panels and insulation. This was then subjected to a hearth designed to duplicate the circumstances in which a severe hearth breaks out of a window.

In December, the federal government launched new fire security laws in response to Dame Judith Hackitt's unbiased evaluation following the Grenfell Tower fireplace. A public inquiry into the fire, which happened in west London in June 2017, heard proof to support the theory that the highly flamable material in the cladding was the first reason for the fireplace's spread.

The helium filling fuel can also be a reasonably good conductor, however solely as long as it stays uncontaminated by fission merchandise. The poorly conducting ceramic fuel pellets are responsible for the majority of the temperature rise. The evolution of the conductivities of the pellet and filling gasoline decide how the thermal performance develops with burnup. As the oxide layer grows, the compressive stress on the outer layer of oxide is not sustained and consequently the tetragonal part turns into unstable and transforms into the monoclinic section. Such a transformation causes the formation of a nice interconnected porosity in the oxide film which permits the oxidizing water to come back in contact with the metal floor.

With the event of an equilibrium pore and crack construction within the oxide layer, the oxidation price effectively becomes linear, a characteristic function of the post-transition oxidation conduct. Alloying components, significantly tin, niobium, and iron, present in the α-strong answer strongly influence both the kinetics and the mechanism of oxide progress in zirconium alloys. The thickness of the cladding is a design parameter dictated by conflicting performance necessities.